Why Powder Coat?

Posted on Sep 11, 2020

We are all familiar with the wet paint process – pigment within a water- or solvent-base is sprayed to coat a surface. While at first glance the results of painting and powder coating may look similar, there are several advantages to powder coating – and its process – over wet painting.

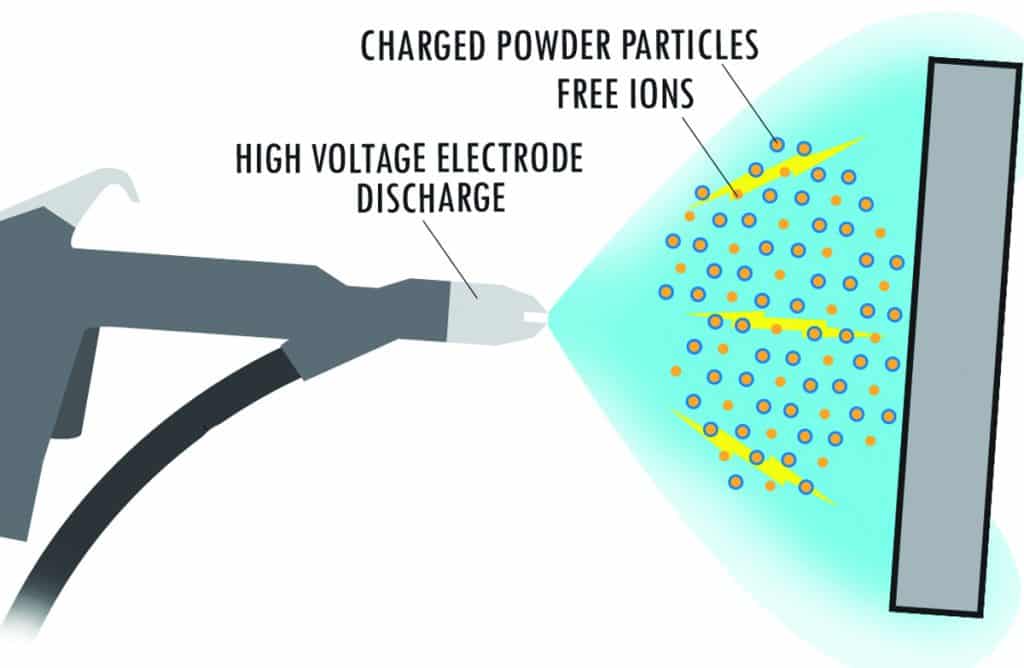

To fully understand the advantages of powder coating, let’s first look at the process. Powder coating is the electrostatic application of organic powdered pigment to a metal surface. The powder is cured by baking, producing a hard, smooth coating.

There are several steps to achieve an effective powder coat finish. First, the metal surface must be cleaned to remove all grease, dirt, or existing coating, and then etched to facilitate a good bond. Once cleaned, the surface must be thoroughly air- or heat-dried.

Once the surface is prepared, the powder can be applied, often using a spray technique. The unique thing about powder coating is that, unlike paint, the powder is dry. What makes it adhere to the surface is that the particles of powder have a negative charge, whereas the part being powder coated is electrically grounded and attracts the powder. The result is a uniformly smooth coating.

To cure and harden the coating, it is placed in a curing oven, where the powder is heated until it flows and a chemical reaction occurs between powder particles.

Greater durability

The chemical bond of powder coating not only makes it the more even coating, but it is also more durable, which means less maintenance:

- Hard, glossy surface that resists corrosion

- 60% greater resistance to solvents

- 74% greater resistance to salt spray

- 94% greater impact resistance

Increased safety.

Increased safety.

Wet paint contains volatile organic compounds (VOCs) which are chemicals dangerous to both the environment and those within the manufacturing environment. On the other hand, powder coating is generally free of VOCs and potentially dangerous solvents.

Powder coating is also more environmentally friendly. Unlike over-sprayed paint, excess powder can be retrieved and reused. Powder coating materials are non-hazardous materials.

Reduced cost

Powder coating is also less expensive than most other organic finishes. In addition, the process is easy to automate, so it often results in reduced labor costs as well. The lack of waste in overspray and disposal costs can also contribute to greater cost-efficiency.

Aesthetic advantage

The pigment within a powder coated finish is generally more vibrant and long-lasting than wet paint. Steel King offers 13 standard colors, including 4 basic and 9 premium colors. Custom colors are also available.