Beam Deflection: When is it a Problem?

Posted on Jun 9, 2020

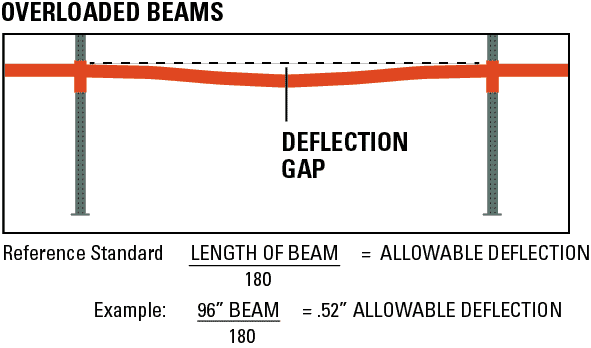

Manufacturer’s beam tables are generally based on uniformly distributed loads. Both the capacity and the beam deflection will vary if the load is not uniformly distributed on the load shelf beams. While some degree of deflection is normal for a loaded rack system, how can you tell when the amount of deflection indicates a reduction in beam capacity?

Helpful Hint: Any beam with visible deformation or cracking of the beam end connectors or welds should be unloaded and replaced. Be sure beams are fully engaged when installed and the safety locks are properly seated.

How to Determine if Beams are Overloaded

1. Observe the beam deflection

The maximum allowed deflection is beam length divided by 180. Deflection greater than this is an overloaded beam. Max deflection is located at beam midpoint for a uniformly distributed load.*

Certain AS/RS or automated systems typically specify a tighter deflection limit for load beams, such as the length of the beams divided by 240 (or 0.42%). This tighter deflection requirement minimizes the risk of the automation (or the load) coming into contact with the beams during placement or removal.

Is there permanent deflection when the beam is unloaded?

If “yes,” the beam has been overloaded and needs to be replaced.

2. Check the connection at the frame

Inspect the area where the beam connects to the frame. If any of the following conditions are present, the beam should be replaced.

- There is any visual deformation of the column and/or clip indicating that the beam was either damaged by impact or overload

- There are any cracks in welded joints

- The safety clip cannot be properly connected and fully engaged.

While beam deflection itself has no bearing on the capacity or safety of your rack, it can affect the rack load and those interacting with the system. As beams deflect, loads can tilt toward each other, increasing the likelihood of contact. This can cause product damage or pose a risk during loading and unloading.

For more information, see RMI’s Load Beam section in its list of Frequently Asked Questions.

*Per RMI Safety Blog Pallet Beam Deflection: How Much is Acceptable? Dated April 30, 2018 article: “However, this deflection limit is not in place to ensure the structural integrity of the beam or rack. Instead, it’s to ensure that personnel interacting with and working around the rack feel safe when they see normal pallet beam deflection. In the 1960s, RMI determined that the calculation length divided by 180 quantified the point at which persons believe the situation is unsafe when deflection in pallet rack is observed.”

Sources used and more information available at:

www.mhi.org

www.rmiracksafety.org

ANSI MH16.1:2012; Specification for the Design, Testing and Utilization of Industrial Steel Storage Racks

RMI Considerations for the Planning and Use of Industrial Steel Storage Racks 3-21-2018

RMI Guideline for the Assessment and Repair or Replacement of Damaged Rack

RMI Safety Blog Pallet Beam Deflection: How Much is Acceptable? Dated April 30, 2018