Rack Inspection Checklist

Posted on Jun 2, 2020

It’s a good idea to be in the habit of regularly inspecting your warehouse storage rack system. While it is also recommended to have a third-party rack inspection specialist periodically conduct a more through inspection, doing a visual inspection at regular intervals reduces the risk factor, as the defects can be easily addressed before they can cause serious damage or injury.

The following checklist can help alert you to any potential issues between inspections.

Rack Environment

| Is lighting adequate? | Installing adequate lighting in your facility is an easy way to help forklift operators see rack uprights and other obstacles that may be in their path. |

| Are aisles clear of clutter? | Keeping traffic areas free of obstacles allows your vehicle operators to take the safest path, maintaining a safe distance between forklifts and rack structures. |

| Is rack protection in place? | Rack protectors are relatively inexpensive and can significantly extend the life and safety of your rack. These can take the form of guard rails, aisle-end guarding, or column protectors that strengthen rack uprights or deflect impact at high risk areas. |

Rack Condition

| Are the racks plumb and level? | Collisions by a forklift may have a greater impact on racks that aren’t set level. And an uneven surface can affect load distribution. This can occur with rack that has been reconfigured or where the foundation may have settled. Rack should be shimmed and plumbed appropriately. |

| Are components rusted or corroded? | This may indicate a couple of potential issues. If paint appears scraped, a rack may have suffered a collision. If rust has formed or is allowed to progress, it may weaken the capacity of your system. |

| Is the rack overloaded? | Along with dislodged beam and forklift damage, overloading is the other primary cause of rack failure. This can happen inadvertently when changes are made to the rack load or profile without checking capacities. Remember that beams have a rated capacity per pair when equally loaded, and that uprights depend to a great degree on beam spacing for their capacity ratings. |

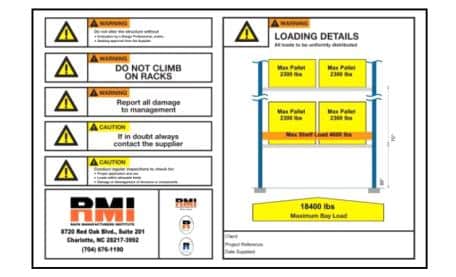

| Are rack load ratings posted? |  Rack capacity may be hard to assess if load ratings are not posted. OSHA recommends that load ratings be present that provide the maximum permissible unit load and/or maximum uniformly distributed load per level, the average unit load, and maximum total load per bay. See ANSI/RMI MH16.1. Rack capacity may be hard to assess if load ratings are not posted. OSHA recommends that load ratings be present that provide the maximum permissible unit load and/or maximum uniformly distributed load per level, the average unit load, and maximum total load per bay. See ANSI/RMI MH16.1. |

Uprights

| Are they bent or damaged?

|

Check the horizontal braces for any bending, twisting, or broken welds. Are there paint scrapes that might indicate an impact? Even minor damage can reduce the upright capacity. Replace or repair these uprights immediately.

To check the degree of damage, measure the gap by placing a straight edge along the surface of the concave side of a damaged rack upright. Center the straight edge on the damaged section’s length as completely as possible. Measure the gap between the upright and the straight edge. If the damage that produces an overall bend in the upright (not just a dent) of more than a few millimeters, this may be cause to replace or repair it. |

| Check your foot plates. | Are they properly lagged to the floor? Are shim stacks nested squarely under the foot plates? |

| Are column protectors installed? | Most often, the best way to address rack damage is to prevent it. Well-placed guard rails and aisle-end protection can prevent a great deal of damage to your system and ensure the safety of your equipment and your workers.

If you have column protectors and notice damage, further inspection is warranted. Often, these items are painted safety yellow for greater visibility. |

| Check bracing. | Are any braces missing? Check thoroughly for any bending or other damage. |

Assembly

| Correct components | Check for incompatible or incorrectly assembled components or improper repairs. |

| Are any components missing or improperly aligned | Check to make sure there are no components that are missing or improperly aligned or nested. Are any components loose? This includes baseplates, shims, spacers, safety clips and pins, anchors, bolts, and safety bars. |

| Safety equipment; load restraint | Are there pallet stops or safety netting adjacent to service aisles? Is there overhead guarding at tunnel bays? |

Beams

| Are the beams properly attached to the uprights? | Are the beams seated tightly into uprights? Has there been impact to the area? Are there broken welds or other signs of damage? Are safety clips still tight; are bolts still tight? |

| Inspect beam surface | Are there any dents, distortion, or evidence of an impact? Be sure to check the beam face and flanges. |

| Are the clips, bolts, or safety pins, or beam attachment pins missing or damaged? | Most racks use some kind of connector hardware aside from the teardrop or keyhole to ensure tight fit and safety. Some even utilize more than one method. Inspect yours to make sure they are all securely fastened and undamaged. |

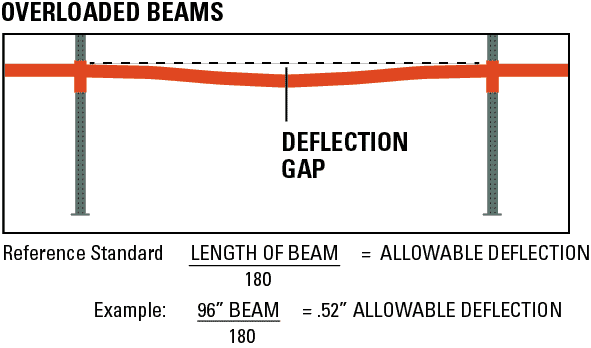

| Check for deflection |  Beams naturally deflect beneath a load, and a certain amount of deflection is acceptable, but it should disappear when you unload the beams. If it doesn’t, the beams need to be replaced, as they have been deformed by overloading or impacts. Beams shouldn’t bow more than 1/180th of the total length of the beam (for a 96” beam, that’s half an inch). Beams naturally deflect beneath a load, and a certain amount of deflection is acceptable, but it should disappear when you unload the beams. If it doesn’t, the beams need to be replaced, as they have been deformed by overloading or impacts. Beams shouldn’t bow more than 1/180th of the total length of the beam (for a 96” beam, that’s half an inch). |

Usage

| Clearance | Check for any loads that are stacked too close to building features, such as sprinkler systems, or are encroaching on the flue space between rows, as this can present a fire hazard. |

| Pallets | Check for any overhanging, double-stacked, or damaged pallets. Are all pallets the correct size for the rack? |

| Safety equipment; load restraint | Are there pallet stops or safety netting adjacent to service aisles? Is there overhead guarding at tunnel bays? |

For more information, visit the Rack Manufacturers Institute (RMI) site website.